Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

In the fast-paced world of leather manufacturing, efficiency and precision are paramount. Automatic CNC leather cutting machines have emerged as game-changers, revolutionizing traditional cutting methods. By leveraging advanced technology, these machines significantly reduce production time while enhancing accuracy and consistency. This article explores how the integration of CNC technology not only streamlines the cutting process but also leads to substantial savings in both time and material costs, positioning manufacturers for greater success in a competitive market.

Leather cutting once relied heavily on manual labor. Skilled workers used hand-held knives, scissors, or rotary cutters to shape leather pieces. This process demanded great precision, but it was slow and prone to errors. Every cut depended on the cutter's skill and attention, leading to inconsistencies in size and shape. Manual cutting also caused higher material waste because it was difficult to optimize the layout of patterns on the leather hide. Workers faced physical strain and safety risks from sharp tools, making the process labor-intensive and sometimes hazardous.

The leather industry gradually embraced automation to overcome these challenges. Early machines offered mechanical assistance but still required significant human input. The real breakthrough came with the introduction of Computer Numerical Control (CNC) technology. CNC leather cutting machines use computer software to control cutting tools, allowing precise, repeatable cuts. Operators upload digital patterns, and the machine executes them automatically. This shift reduced dependence on manual skill, cut production time, and improved overall accuracy.

Automation also introduced features like automatic material feeding and nesting. Nesting software arranges patterns on the leather hide to maximize material use and minimize waste. This technology transformed leather cutting from a craft into a streamlined industrial process, capable of handling large volumes efficiently.

CNC technology revolutionized leather cutting by boosting speed, precision, and consistency. Machines cut complex shapes and curves with clean edges, impossible to achieve manually. They can cut multiple layers simultaneously, increasing throughput. The digital control ensures every piece matches design specifications exactly, improving product quality and reducing rejects.

Material utilization improved significantly. CNC nesting algorithms optimize pattern placement, reducing scraps by 2-5% or more, depending on design complexity (example figure, needs verification). This translates into substantial cost savings, especially since leather is an expensive raw material.

Safety also improved. Automated cutting reduces workers' exposure to sharp blades and repetitive cutting motions, lowering injury risks and physical strain.

In summary, CNC machines transformed leather cutting into a faster, safer, and more cost-effective process. They enable manufacturers to meet higher demand without sacrificing quality, positioning them well for future growth.

When transitioning from manual to CNC leather cutting, invest time in training operators on nesting software to maximize material savings and production efficiency.

Automatic CNC leather cutting machines use high-precision cutting heads that move rapidly and accurately. These cutting heads can handle various leather types, from soft to thick, without damaging the material. The blades operate at high frequencies, sometimes reaching 20,000 vibrations per minute, allowing clean, sharp cuts. This precision ensures every piece matches the digital design exactly, reducing errors and the need for rework. Complex shapes, curves, and fine details are cut flawlessly, something manual tools struggle to achieve consistently.

These machines come with automatic material feeding systems that smoothly and continuously supply leather to the cutting area. This feature reduces setup time and keeps the production line moving without interruption. Coupled with advanced nesting software, the machine arranges cutting patterns on the leather hide to use space efficiently. The nesting system quickly calculates the best layout, avoiding defects and minimizing scraps. This optimization can improve leather utilization by 2% to 5% or more, saving costly material and lowering production expenses.

CNC leather cutting machines integrate with CAD/CAM software, allowing users to input complex digital designs easily. The machines can replicate intricate patterns and even mark stitching or cutting lines automatically on the leather surface. This reduces errors during assembly and speeds up downstream processes. Operators can customize designs quickly, enabling flexible production runs and faster response to market demands. The software also supports multi-layer cutting and multi-zone operations, increasing throughput and allowing simultaneous processing of different leather types or thicknesses.

To maximize material savings, invest time in mastering the nesting software that comes with your CNC leather cutting machine, as efficient nesting directly boosts leather utilization and reduces waste.

Automatic CNC leather cutting machines dramatically boost production speed. Unlike manual cutting, they operate continuously without fatigue, cutting leather faster and more precisely. The high-frequency vibration blades move rapidly, slicing through multiple layers at once. This capability reduces turnaround time and helps manufacturers meet tight deadlines.

The machines also automate material feeding, eliminating delays caused by manual handling. Operators simply upload digital designs, and the machine executes cuts quickly and accurately. This streamlined workflow allows businesses to increase output without compromising quality.

Material waste is a major cost factor in leather manufacturing. CNC machines minimize waste through intelligent nesting software. This software optimizes pattern layout on leather hides, maximizing usable area and avoiding defects or blemishes.

By arranging pieces efficiently, the software can increase leather utilization by 2% to 5% or more, depending on the design complexity (example figures, need verification). This reduction in scraps translates into significant savings on expensive raw materials.

Additionally, the machines’ precision cuts prevent errors that lead to wasted pieces. Consistent cutting reduces rejects, further lowering material loss.

CNC leather cutting machines deliver unmatched consistency. The digital control ensures every cut matches the exact dimensions specified in the design files. This precision eliminates variability caused by human error in manual cutting.

The machines handle complex shapes, curves, and fine details flawlessly. This accuracy improves product quality, ensuring each piece fits perfectly during assembly. It also reduces the need for rework or adjustments downstream.

Consistent quality is crucial for brands maintaining high standards and customer satisfaction. CNC machines provide reliable results batch after batch, supporting scalable production without quality dips.

Regularly update and calibrate your CNC machine’s nesting software to maintain optimal material utilization and keep production efficient.

Automatic CNC leather cutting machines greatly reduce labor costs by automating tasks once done manually. Traditional leather cutting requires skilled workers to measure, cut, and arrange patterns by hand. This process demands time, training, and physical effort. CNC machines need fewer operators, mainly to oversee the process and load materials. This shift lowers wage expenses and reduces the need for extensive staff training.

Automation also cuts down on human errors, which can lead to costly rework or wasted materials. By minimizing manual intervention, businesses save both time and money. Furthermore, workers can be reassigned to more valuable roles such as quality control or design, increasing overall workforce efficiency.

Leather is an expensive raw material, so reducing waste directly impacts profitability. CNC machines use advanced nesting software that arranges patterns optimally on the leather hide. This software considers defects and irregular shapes, placing pieces to maximize usable area.

Studies and user reports show nesting optimization can improve material utilization by 2% to 5% or more, depending on design complexity (example figures; verification recommended). This seemingly small percentage translates into significant cost savings over large production volumes.

Precise cutting also prevents errors that cause scrap. Unlike manual cutting, CNC machines produce consistent, clean cuts, reducing rejects and off-cuts. Less waste means lower raw material costs and a more sustainable manufacturing process.

Although CNC leather cutting machines require upfront investment, their cost-effectiveness leads to a quick return on investment (ROI). Savings in labor costs and material waste add up quickly. Faster production speeds increase throughput, allowing businesses to fulfill more orders and boost revenue.

Many manufacturers report recouping their investment within months to a couple of years, depending on production volume and machine usage. The machines also enhance product quality and consistency, which can improve brand reputation and customer satisfaction, indirectly contributing to profitability.

Automation reduces downtime and maintenance costs compared to older manual or semi-automated equipment. Modern CNC systems often come with real-time monitoring and diagnostics, helping prevent costly breakdowns and ensuring continuous operation.

Calculate your expected material savings and labor reductions before purchasing a CNC machine to estimate ROI and choose a model that fits your production scale and goals.

Automatic CNC leather cutting machines greatly improve workplace safety. They replace manual cutting tools that pose risks of cuts and injuries. The blades operate inside enclosed systems or protected areas, limiting direct contact with operators. Sensors and emergency stop features add extra layers of protection. Because machines automate repetitive cutting tasks, workers avoid fatigue and reduce the chance of mistakes caused by tiredness. This safer environment lowers injury rates and helps companies comply with occupational safety standards.

CNC leather cutting machines support sustainability by minimizing material waste. Their nesting software arranges patterns to use leather hides efficiently, reducing scraps. Less waste means fewer discarded materials and lower raw material demand, which benefits the environment. Additionally, optimized cutting reduces energy consumption per unit produced, since machines work faster and more precisely. Some modern machines also feature energy-saving modes and use eco-friendly components. By cutting waste and energy use, these machines help manufacturers adopt greener production methods.

Manual leather cutting involves repetitive motions and handling heavy materials, leading to physical strain and potential musculoskeletal problems. CNC machines automate the cutting process, eliminating the need for workers to perform strenuous tasks repeatedly. Operators mainly oversee the machine and manage material loading, which is less physically demanding. This reduction in manual labor decreases fatigue and improves overall worker well-being. Healthier workers mean fewer absences and higher productivity, benefiting both employees and businesses.

Regularly maintain and update safety features on your CNC leather cutting machines to ensure optimal protection for operators and a safer workplace environment.

Choosing the right CNC leather cutting machine is crucial for maximizing your business’s efficiency and profitability. Start by evaluating your production volume. High-volume manufacturers need machines with faster cutting speeds and larger cutting beds to handle bigger leather hides and multiple layers simultaneously. Smaller operations might prioritize compact machines with flexible features for custom jobs.

Consider the types of leather you work with. Some machines handle thick, tough hides better, while others excel at delicate, thin leather. Check the machine’s blade options and cutting head technology to ensure compatibility with your materials.

Software compatibility matters too. Look for machines that integrate smoothly with your existing CAD/CAM systems. Advanced nesting software that optimizes leather usage can save significant material costs.

Don't overlook machine reliability and support services. Choose brands known for durable machines and responsive customer service. Training and maintenance packages also add value, helping minimize downtime and keep production running smoothly.

Every leather business has unique requirements. Customizing your CNC machine setup can enhance productivity. For example, if your products require complex patterns, prioritize machines with advanced design and multi-tool capabilities. Some models offer automatic marking for stitching lines, reducing assembly errors.

If you produce various leather products, a machine with multi-zone or multi-head cutting can handle different materials or patterns simultaneously. This flexibility boosts throughput and reduces changeover time.

Consider adding features like automatic material feeding or conveyor systems for continuous operation. These upgrades reduce manual handling and speed up production cycles.

Customization extends to software too. Tailoring nesting algorithms to your specific product shapes and leather grades can maximize material use and reduce waste.

Investing in a CNC leather cutting machine is a long-term decision. Future-proof your purchase by choosing technology that can grow with your business. Machines that support software updates and new cutting tools help you stay competitive as designs and materials evolve.

Look for equipment that offers scalability. Modular machines allow adding cutting heads or expanding cutting areas later without full replacement. This flexibility saves costs as demand increases.

Energy efficiency is another factor. Modern machines with energy-saving modes reduce operating costs and environmental impact.

Finally, consider the machine’s data capabilities. Real-time monitoring and diagnostics help maintain uptime and optimize performance. Integration with factory automation systems can streamline workflows and improve overall efficiency.

Before buying, assess your production needs and growth plans carefully, then choose a CNC leather cutting machine that offers flexibility, reliable support, and software compatibility to maximize your investment’s value.

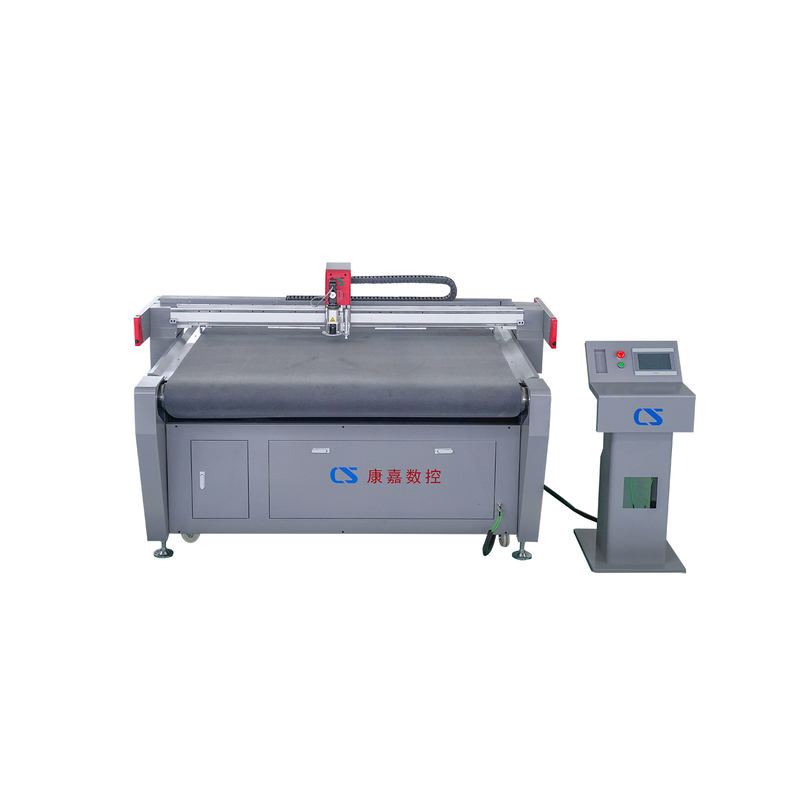

Continued advancements in automation revolutionize leather manufacturing, enhancing speed and precision. As the industry evolves, predictions suggest increased reliance on CNC technology for efficiency and sustainability. CNC leather cutting machines offer unmatched consistency and material savings, transforming production processes. Jinan Kangjia CNC Equipment Co., Ltd provides cutting-edge solutions that maximize productivity and reduce costs. Their machines deliver high-quality results, making them invaluable assets for businesses aiming to stay competitive in a rapidly changing market.

A: Automatic CNC Leather Cutting Machines are advanced devices that use computer software to control cutting tools for precise, repeatable cuts in leather, enhancing production efficiency and reducing manual labor.

A: These machines increase efficiency by automating cutting tasks, using high-precision cutting heads, and optimizing material use with nesting software, thus reducing waste and speeding up production.

A: They reduce labor costs, minimize material waste, and increase production speed, leading to rapid ROI and significant long-term savings.

A: Consider production volume, leather types, software compatibility, machine reliability, and potential for future upgrades to ensure the machine meets your business needs.

A: They reduce direct contact with cutting tools, automate repetitive tasks, and include safety features like sensors and emergency stops, lowering injury risks.