Views: 0 Author: Site Editor Publish Time: 2025-06-26 Origin: Site

CNC leather cutting machines are revolutionizing leatherwork with precision and speed. But why should you choose one? In this post, we’ll explore the key benefits of CNC technology, from increased efficiency to reduced material waste. You’ll learn how investing in a CNC leather cutting machine can elevate your craftsmanship and streamline production.

A CNC leather cutting machine uses computer-controlled systems to cut leather into precise shapes and designs. Unlike traditional cutting methods, which rely on hand-held tools and human effort, CNC machines automate the process, ensuring high precision and speed. CNC cutting eliminates human error, giving consistent results across large production runs. It’s ideal for industries that need consistent, intricate, and large-scale leather cuts, such as fashion, upholstery, and automotive industries.

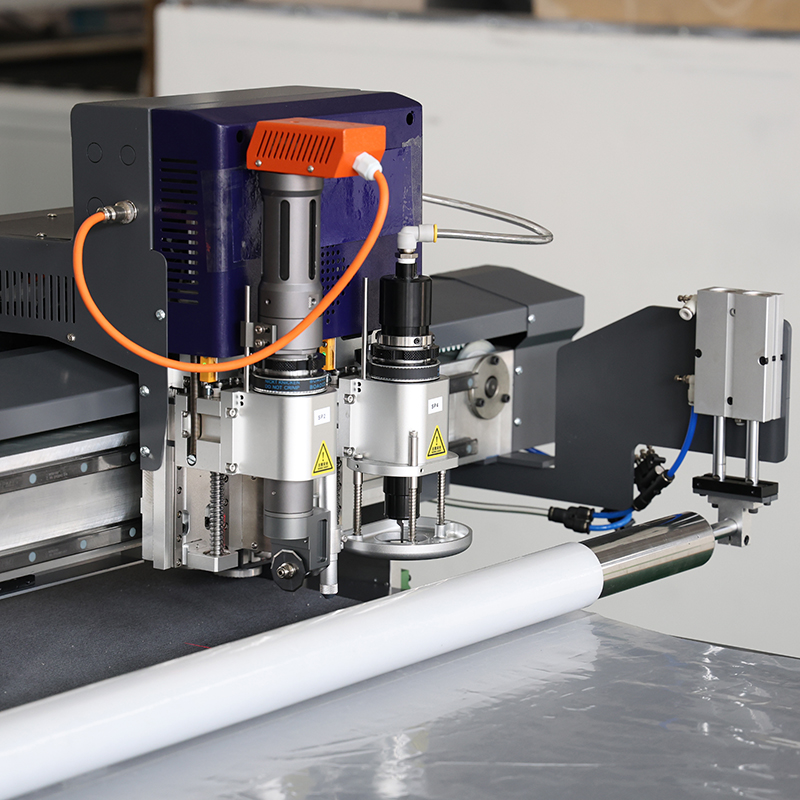

A CNC leather cutting machine consists of several key components:

Blade: The cutting tool used to precisely slice through leather.

Digital Controller: A computer system that receives design files and controls the cutting process.

Cutting Bed: The surface where the leather is placed, allowing the machine to cut multiple layers at once.

Motors and Actuators: These move the blade and leather, following the digital design paths.

Together, these components enable the machine to perform detailed and efficient cuts with minimal human intervention.

The process of using a CNC leather cutting machine involves several steps:

Design Creation: A digital design is created using CAD (Computer-Aided Design) software.

Pattern Nesting: The design is uploaded to the CNC machine, and the software arranges patterns on the leather to minimize waste.

Material Setup: The leather is placed flat on the cutting bed to ensure it is properly aligned.

Cutting: The CNC machine follows the programmed design, cutting the leather with an oscillating knife or blade.

Inspection: After cutting, the leather pieces are inspected for quality and prepared for further processing.

This automated process makes leather cutting faster, more precise, and highly efficient compared to traditional methods.

CNC leather cutting machines offer superior precision compared to manual methods. The digital controls ensure consistent cuts, making them ideal for intricate designs and high-quality products. Whether you're creating detailed patterns for fashion or upholstery, CNC machines provide the accuracy necessary to maintain uniformity across every piece.

CNC machines drastically improve cutting speed, allowing businesses to meet tight deadlines. They can cut multiple layers of leather at once, speeding up production and reducing labor costs. This increased efficiency results in faster turnaround times, making CNC machines a valuable asset for businesses needing high-volume output.

CNC leather cutting machines can handle various leather thicknesses, from soft materials to thick hides. They can also cut complex patterns and shapes that traditional methods struggle with. Whether you need straight lines, curves, or custom designs, CNC machines provide the flexibility to meet your specific needs.

One of the key advantages of CNC machines is their ability to optimize material usage. Through nesting technology, the machine arranges patterns in the most efficient way possible, minimizing leftover material. This not only reduces waste but also helps businesses save money on materials, improving the overall cost-efficiency of production.

Using a CNC machine improves safety in the workplace. Unlike manual cutting methods, CNC machines reduce the need for workers to handle sharp tools, lowering the risk of injuries. The automation of the cutting process ensures a safer working environment while maintaining high productivity.

In the fashion industry, CNC leather cutting machines provide precision for cutting complex patterns in clothing, bags, and accessories. Designers can input detailed designs into the machine, ensuring consistent, accurate cuts every time. This technology enables fast production of leather products with high precision, perfect for large-scale or custom fashion collections.

CNC leather cutting machines play a crucial role in automotive interiors, including cutting leather for seats, dashboards, and trim. Their precision ensures each piece fits perfectly into the vehicle's design. In furniture manufacturing, CNC machines are used to cut leather upholstery for chairs, sofas, and other furniture items, providing uniformity and speed in production.

For artisans and small businesses, CNC leather cutting machines are a game-changer. These machines allow the creation of custom leather items like belts, wallets, and accessories with intricate details. The accuracy of CNC machines makes it easier to replicate designs and produce high-quality products, elevating craftsmanship and reducing labor costs.

CNC leather cutting machines are essential in industrial settings where large volumes of leather goods need to be produced consistently. These machines offer high-speed cutting while maintaining precise quality control. Whether producing car seats or furniture pieces, CNC technology ensures efficiency, reducing errors and ensuring uniformity in mass production.

When selecting a CNC leather cutting machine, ensure it fits comfortably in your workspace. Consider the size of the leather materials you'll be cutting. If you plan to work with large hides or bulky projects, choose a machine with a larger bed size to accommodate your needs. A compact machine might be ideal for smaller, more intricate cuts, but larger operations require more space for efficiency.

It’s crucial to ensure the CNC leather cutting machine is compatible with CAD (Computer-Aided Design) software. This compatibility allows for greater design flexibility, enabling you to upload detailed patterns directly to the machine. Being able to work with popular design software ensures your creative ideas are easily transformed into precise cuts.

Different leather types and cutting tasks may require different blades or tools. Look for a machine that offers a variety of blade options. For instance, oscillating blades work well for precision, while rotary blades are better for smooth and continuous cuts. The availability of different tools will allow you to adapt to various leather thicknesses and textures, providing more versatility.

Advanced automation features, like automatic nesting and auto-feed systems, can significantly boost productivity. Automatic nesting optimizes material usage by arranging patterns to minimize waste, while auto-feed systems allow for continuous cutting, reducing the need for manual intervention. These features are perfect for businesses looking to streamline operations and increase output.

Choose a CNC machine that is easy to maintain and has good support options. Regular maintenance is essential to keep the machine running smoothly, and having access to technical support ensures quick solutions to any issues. Look for machines with simple maintenance routines and providers that offer customer support, training, and spare parts to avoid prolonged downtime.

The upfront cost of a CNC leather cutting machine can be significant, but it offers long-term savings. While manual labor can be costly and inefficient, CNC machines reduce the need for excessive labor. They also minimize material waste through precise cutting and optimization. Over time, these savings outweigh the initial cost, making it a worthwhile investment for businesses.

Operating a CNC leather cutting machine comes with some ongoing expenses. These include power consumption, maintenance, and the cost of consumables like blades and software updates. However, these costs are generally lower than the expenses associated with manual labor. Plus, CNC machines can run continuously, boosting productivity and reducing downtime.

A CNC leather cutting machine can significantly improve ROI. By cutting leather faster and more precisely, businesses can increase output and reduce errors, leading to higher-quality products. Additionally, lower material waste and less labor mean lower overall costs. The increased efficiency and reduced need for rework will result in higher profit margins over time.

To keep your CNC leather cutting machine running smoothly, follow these key maintenance steps:

Clean the Machine Regularly: Dust and debris can affect the machine's performance. Clean the cutting bed, blade, and other surfaces to ensure smooth operation.

Check the Blade: Inspect the blade for wear or dullness. Replace it as needed to maintain cutting precision and avoid unnecessary friction.

Lubricate Moving Parts: Apply lubricant to moving parts such as the machine’s arms and guides. This helps reduce friction and wear, ensuring longevity.

Inspect and Replace Filters: Clean or replace the air filters regularly to prevent dust buildup and ensure the machine operates efficiently.

Regular maintenance will keep your CNC leather cutting machine in top condition and prevent unnecessary downtime.

CNC leather cutting machines are designed for precision, but issues can arise. Here’s how to troubleshoot common problems:

Calibration Issues: If the cuts aren’t precise, check the machine’s calibration settings. Adjust the settings according to the manufacturer’s guidelines to restore accuracy.

Cutting Inconsistencies: If you notice uneven cuts, the blade may be dull, or there could be material buildup on the machine. Clean the blade and ensure proper material setup before cutting.

Software Glitches: Ensure that the software is up-to-date and compatible with the machine. If the machine isn't responding correctly, try restarting both the software and the machine.

Machine Overheating: If the machine is overheating, ensure proper ventilation and check for any mechanical issues, like blockages or fan malfunctions.

By addressing these common issues early, you can extend the lifespan of your CNC leather cutting machine and avoid costly repairs.

CNC leather cutting machines offer precision, efficiency, and versatility, making them invaluable for various leather applications. Investing in CNC technology can enhance product quality and streamline production. Explore available options and consult manufacturers to find the perfect CNC leather cutting machine for your business needs.

A: CNC leather cutting machines offer high precision, speed, and consistency in cutting. They reduce material waste, improve efficiency, and allow for intricate designs. These machines also ensure uniformity across multiple cuts, making them ideal for large-scale production and custom leather goods.

A: CNC leather cutting machines use a computer to control the blade's movements, cutting leather into precise shapes and patterns. Users input designs via CAD software, and the machine automatically follows these instructions, ensuring high accuracy and clean edges.

A: You should invest in a CNC leather cutting machine when you require consistent, high-quality cuts, reduce material waste, and increase production efficiency. These machines are perfect for businesses looking to scale their operations or improve precision in their leatherwork.